THE PENTA SERIES 110

THE PENTA SERIES Plastic Injection Moulding Machines

Key Features

- Designed in India for Indian Conditions

- Made in India

- Fully up-gradable for a long and Profitable Operating Life

- Maintained by us for a worry free Ownership and Operating experience

- The machine has a single integrated casting as a base for exceptional rigidity and durability.

In the Clamping Unit

- Hard chrome plated Tie Bars

- High strength Brass Bushes with embedded graphite, running on the Tie Bars

- Moving platen guide shoes for low friction but fast and stable mold movement, again embedded with graphite as a Lubricant.

- Adjusting all 4 Tie Bars for equal tonnage force.

- Auto Lubrication for all Toggle Points with the Lubricant distribution system all around

- A Mould height adjusting hydraulicpowered Gear Mechanism with a sensor for rough and fine adjustments.

- Large space between Tie Bars for adapting more sizes of Moulds and multi capacity Moulds.

- T-slot Moulds clamping mechanism for easy Mould loading and unloading.

In the Injection Unit

- Twin-cylinder balanced Injection unit

- Injection unit and the Hydro unit move on the Linear Motion Guide for low friction and fast movement

- A 5 stage Injection, 2 stage hold-on and 3 stage charging.

- Post and pre suck back option

- Injection speed display on graph

- Nozzle contact force through Non Return Valve

- Nitrided barrel and Nitrided hard Chromed Screw

- A high torque Hydraulic Motor

- Material cold start protection

- Accurate PID heat control

- Mechanical adjustment of Injection unit in respect to fixed Platen centre

- Barrel protection

- Purge cover

- Auto Purging options

Control Unit

- High Response Controller

- All Switchgears by L & T

- High precision proportional Pressure and Flow control

- Full color Display

- Closed loop PID Temperature control

- 120 sets of Mould Memory

- Quality control page displaying “Cushion, Open –Close- Injection Cycle time" parameters

- Production Chart showing per hour produced pieces and rejections

- Screw rotation Speed Display

- Automatic Fault Detection & Display

- USB for data uploading and downloading

- Input/Output texting function on-board Diagnosis

- Emergency buttons for rear and front safety doors

- Alarm light with buzzer

Hydraulic System

- Hydraulic Valves from Rexroth

- Hydraulic Circuit designed to meet International Safety Standards

- Hydraulic Oil regeneration circuits

- Servo Hybrid system

- High response closed loop Hydraulic System

- High Operating efficiency of around 95-98%

- Low wastage of power hence high Power Saving

- Better life of Hydraulic Seals, Oil and Valves

- Low water consumption

- Improved Precision Cycle and Repeatability

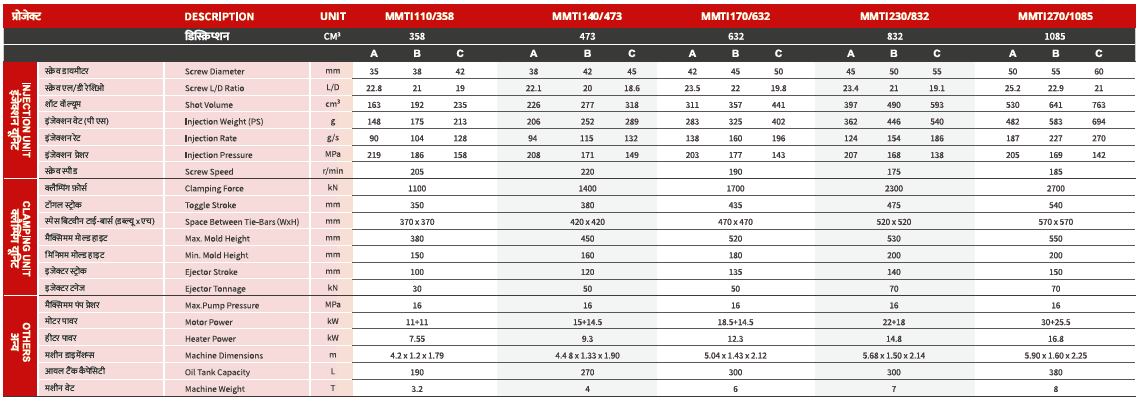

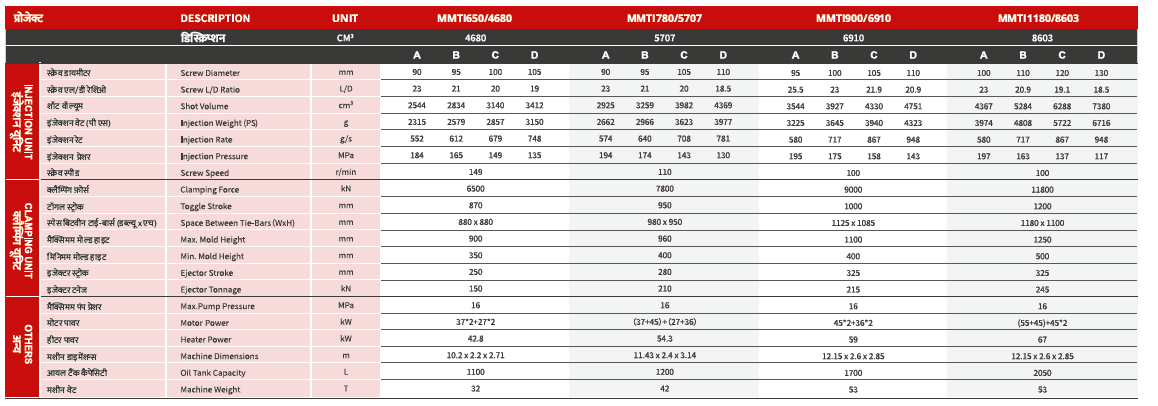

SPECIFICATIONS